Why Taper Bearing Pakistan is Essential In Industrial Growth

Introduction

When it comes to industrial growth, Pakistan has been making significant strides in recent years. A key component driving this growth is the use of taper bearing Pakistan. But what exactly are taper bearings, and why are they so crucial to various industries in Pakistan? Let’s dive in and explore the multifaceted role these components play in bolstering industrial efficiency and economic development.

Understanding Taper Bearing Pakistan

What are Taper Bearings?

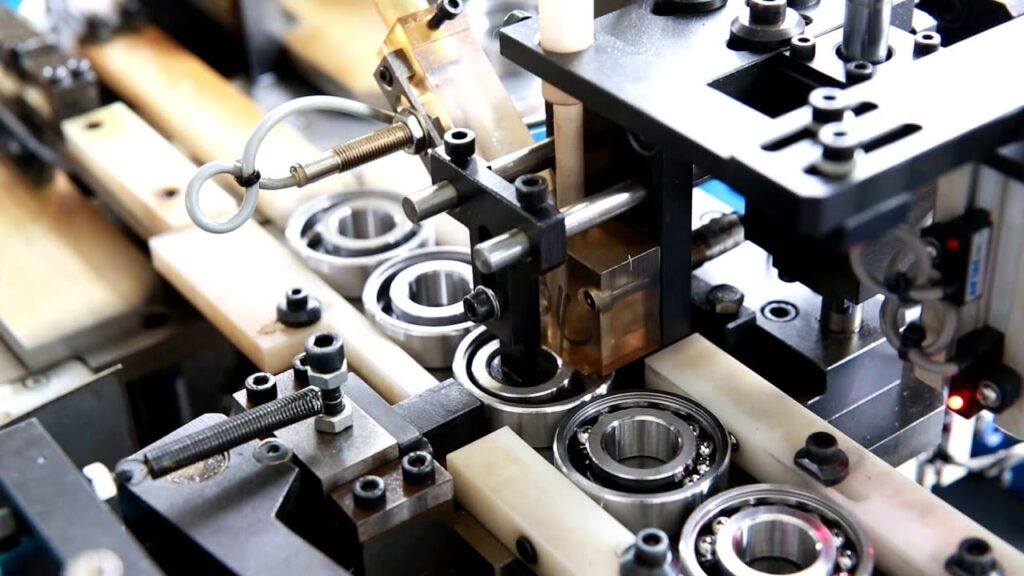

Taper bearing Pakistan is a type of rolling-element bearing designed to handle large radial and axial loads. They consist of an inner ring, an outer ring, and a set of tapered rollers between them. The conical geometry of these rollers allows them to manage both the direction and magnitude of the loads efficiently.

Key Features of Taper Bearings

Taper bearings are known for their high load-bearing capacity, durability, and ability to operate smoothly under high-stress conditions. Their design helps in evenly distributing the loads, reducing friction, and increasing the lifespan of the machinery they are part of.

Historical Context

Evolution of Taper Bearings in Industry

Taper bearings have been around for decades, evolving with advancements in technology. Initially used in simple mechanical applications, they have now become integral to complex industrial machines and systems due to their reliability and performance.

Introduction of Taper Bearings Pakistan

In Pakistan, the introduction of taper bearings marked a significant turning point in industrial business development. With the establishment of local manufacturing units and the import of high-quality bearings, Pakistan’s industries started experiencing enhanced performance and efficiency.

Types of Taper Bearings

Single-Row Taper Bearings

These bearings are the most common type and are used in applications where there is a need to support combined loads.

Double-Row Taper Bearings

Double-row taper bearings are used in applications requiring high radial and axial load support in both directions. They are ideal for heavy-duty machinery.

Four-Row Taper Bearings

Four-row taper bearings are designed for use in large machinery like rolling mills. They offer superior load capacity and are highly durable.

Applications of Taper Bearings in Various Industries

Automotive Industry

In the automotive industry, taper bearings are essential in the construction of wheels, gearboxes, and engines. They help in reducing friction, which enhances vehicle performance and longevity.

Manufacturing Industry

Manufacturing processes involve high-speed operations and heavy loads. Taper bearings are crucial in ensuring that machines run smoothly and efficiently without frequent breakdowns.

Construction Industry

Heavy machinery used in construction, such as cranes and bulldozers, rely on taper bearings for stability and load management. This ensures that these machines can handle heavy materials and operate under tough conditions.

Mining Industry

The mining industry uses taper bearings in equipment like conveyor belts and drilling machines. These bearings can withstand the harsh conditions of mining environments, providing reliability and reducing maintenance costs.

Advantages of Taper Bearings

Durability and Longevity

Taper bearings are built to last. Their robust design and high-quality materials make them highly durable, reducing the need for frequent replacements.

Load-Bearing Capacity

One of the standout features of taper bearings is their ability to handle large loads. This makes them suitable for heavy-duty applications across various industries.

Efficiency in High-Stress Environments

Taper bearings maintain their performance even in high-stress environments, making them ideal for industries that operate under extreme conditions.

Taper Bearings and Industrial Efficiency

Enhancing Machinery Performance

By reducing friction and wear, taper bearings enhance the overall performance of machinery. This leads to smoother operations and higher productivity.

Reducing Maintenance Costs

With their durability and reliability, taper bearings help in cutting down maintenance costs. Industries can save significant amounts on repairs and replacements.

Improving Operational Efficiency

Efficient machinery leads to better operational efficiency. Taper bearings contribute to this by ensuring that machines run without hiccups, thereby increasing the output.

Economic Impact of Taper Bearings in Pakistan

Contribution to GDP

The manufacturing and application of taper bearings contribute significantly to Pakistan’s GDP. By supporting key industries, these bearings help in driving economic growth.

Employment Generation

The taper bearing industry provides employment opportunities at various levels, from manufacturing to maintenance, thereby supporting livelihoods and reducing unemployment.

Supporting Small and Medium Enterprises (SMEs)

SMEs involved in the production and maintenance of taper bearings benefit from the demand generated by larger industries. This support helps in nurturing a robust industrial ecosystem.

Challenges in the Taper Bearing Industry

Supply Chain Issues

The industry faces challenges related to the supply chain, including the availability of raw materials and timely delivery of components.

Quality Control

Maintaining high standards of quality is crucial. The industry must ensure that bearings meet stringent specifications to perform reliably.

Technological Advancements

Keeping up with technological advancements is essential for staying competitive. The industry needs continuous innovation to improve bearing designs and materials.

Future Prospects of Taper Bearings in Pakistan

Technological Innovations

The future of taper bearings in Pakistan looks promising with ongoing technological innovations. Advancements in materials and manufacturing processes are expected to enhance bearing performance.

Expanding Market Demand

As industries continue to grow, the demand for high-quality taper bearings is expected to rise. This presents significant opportunities for local manufacturers.

Government Support and Policies

Government initiatives aimed at promoting industrial growth and manufacturing are likely to support the taper bearing industry. Policies that encourage local production and technological upgrades will be beneficial.

Conclusion

In summary, taper bearing Pakistan plays an essential role in the industrial growth of Pakistan. Their ability to enhance machinery performance, reduce maintenance costs, and improve operational efficiency makes them indispensable across various sectors. As the industry continues to evolve, the future of taper bearings in Pakistan looks bright, promising further economic development and industrial advancement.

FAQs

What are taper bearings used for?

Taper bearings are used in applications that require high load-bearing capacity and efficiency, such as automotive, manufacturing, construction, and mining industries.

How do taper bearing Pakistan work?

Taper bearing Pakistan work by using tapered rollers to handle large radial and axial loads. The conical design helps in distributing the loads evenly, reducing friction, and enhancing durability.

Why are taper bearings important in the automotive industry?

In the automotive industry, taper bearings are crucial for reducing friction in wheels, gearboxes, and engines, which enhances vehicle performance and longevity.

What are the challenges faced by the taper bearing industry in Pakistan?

The industry faces challenges such as supply chain issues, maintaining quality control, and keeping up with technological advancements.

What is the future outlook for the taper bearing market in Pakistan?

The future looks promising with technological innovations, expanding market demand, and supportive government policies expected to drive growth in the taper bearing market.

For more information: SBS Bearings

Leave Your Comment